Porous

Porous

HOME > Products > Porous

Porous

Porous Ceramic is a sintered body made of numerous pores by applying ceramic sintering technology, unlike conventional Adsorption Plates..

Recently, it is widely used as a base material for various industries such as various filters, high temperature refractories(Kiln Furniture) materials, absorbent materials, sound absorbing materials, lightweight structural materials, and heat insulating materials.

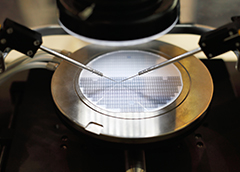

In particular, the process of thin film adsorption required in the semiconductor, LED and display production field is also being utilized in Vacuum Adsorption technology with high performance. CMTX Co., Ltd. understands the needs of customers and designs and manufactures the most suitable products for the use environment.

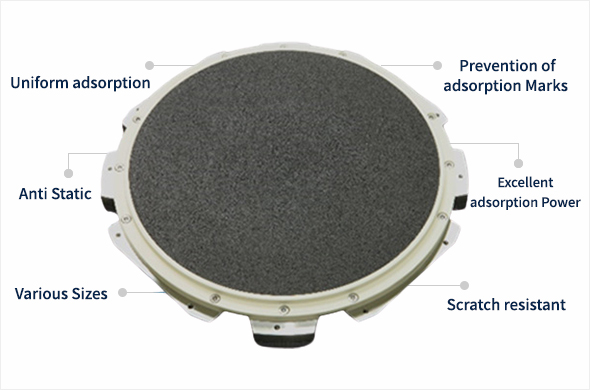

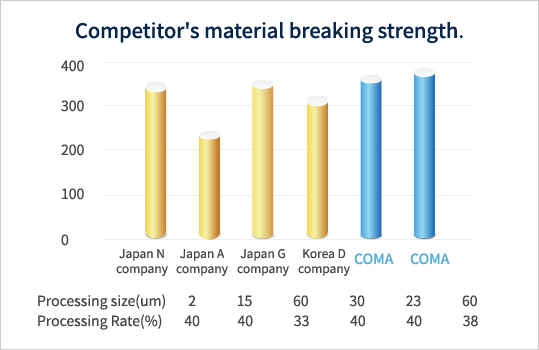

Porous ceramics have a high porous rate, but it is important to maintain its high-intensity properties, especially in the Semiconductor and Display sectors where it should maintain a uniform porous rate and have good surface illumination to avoid damaging the product which has been emerged as a big problem recently.

Porous ceramics have a high porosity, but the higher the porosity, the lower the strength of the material .In addition, a low porosity means that the porosity decreases or the size of the pores increases relatively at a certain porosity, so materials with low porosity have a problem of inferior strength.

CMTX Co., Ltd. understands the needs and problems of customers and designs and produces the most suitable products for the use environment.

| Porous Product Specifications | |

|---|---|

| Main Ingredient | Al203, SiC (above 99%) and more |

| Pore size | 2~120 um (Major Product 60um approx) |

| Porosity | 35~40% |

| Color | Dark Gray, Brown, White (Color varies as per variation in Pore size) |

| Size | Maximum D520 (Based on material Production) |

| Surface Resistance(Ω) | 10^6 ~ 10^10 Ω㎠ |

-

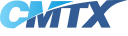

Prevention of Adsorption Marks

With Uniform Pore distribution (porosity around 40 %) and small pore sizes do not leave the adsorption marks caused by adsorption holes that occurs in existing Vacuum Chucks. It is especially useful for the Thin Film Process.

-

Uniform Adsorption Power

Uniform Pores are distributed on the entire surface of the vacuum plate, so that the entire surface is absorbed with a uniform pressure. It is very advantageous for adsorption of products like Bending Film .

-

Anti Static Effect

It has excellent electrostatic dissipation and has excellent electrostatic removal effect , As the surface resistance of the product itself is maintained at 10^6 to 10^9 Ωcm2, CMTX's Porous Ceramics has the effect of slowly removing static-bearing products during the manufacturing process.

-

Scratch Protection

Excellent surface illumination ensures no scratches on the surface of the product.. CMTX’s product with smooth surface finish and even pore distribution ensures that the film and glass surface remains scratch–free.

-

Various Size

Capability to make such chucks of various size and shapes. CMTX specializes in processing Semiconductor Parts and Materials such as Ceramics and Sapphires, and guarantees our clients with the quick response and the best quality. CMTX covers all processes from Vacuum Chuck Base processing, Porous Processing, Bonding and other Post Processing.